Every year IMO brings numerous updates to the way we run our ships.

And every year, ship owners, ship managers, seafarers, and everyone else have to scramble to catch up with these updates.

One such area that has seen many updates from IMO is the “air pollution“.

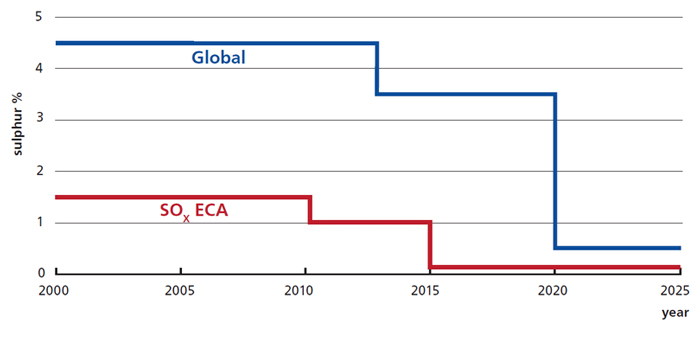

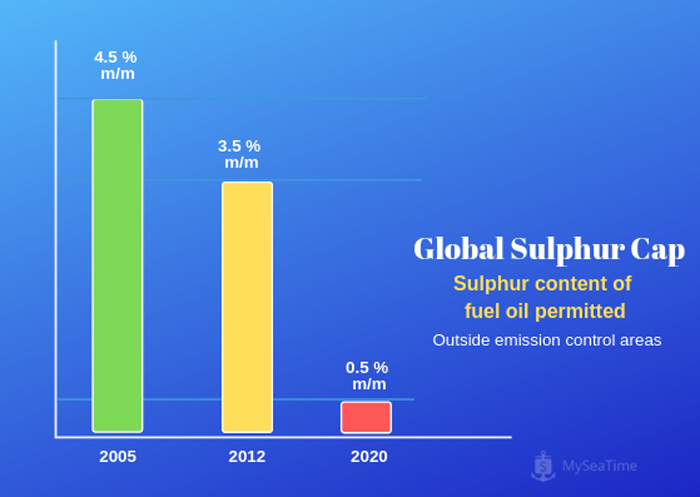

Since 2005, IMO has been working on to gradually reduce the SOx emission from the ships.

It was desired to eventually come down to permitting the fuel with maximum sulphur content of 0.5%.

Come 01st January 2020, the long wait will finally be over.

But many see this as a challenge to comply with this change.

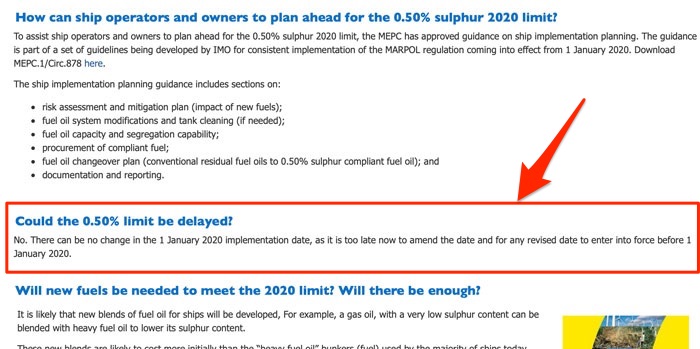

And many shipowners expect that the IMO would shift 01st Jan 2020 deadline to a date beyond that.

However, IMO has clarified that there would not be any extension to this deadline. So the 01st Jan 2020 deadline to comply with new SOx requirements would remain.

And to deal with this challenge, ship owners and managers need to devise the perfect strategy quickly.

In this blog, we will discuss about the challenges and options available to the ship owners and ship managers.

But first, let us get a clear picture of what the IMO requirement really is.

IMO Sulpher 2020

MARPOL Annex VI, Regulation 14 deals with the requirements related to the SOx emission.

Here is what regulation 14 states.

The sulphur content of any fuel oil used on board ships shall not exceed the following limits:

- 4.50% m/m prior to 1 January 2012;

- 3.50% m/m on and after 1 January 2012; and

- 0.50% m/m on and after 1 January 2020

The requirements for the emission control area are more stringent but for the scope of this article, we will not discuss the emission control areas.

Presently the ships are allowed to use fuel with maximum sulphur content of 3.5% m/m.

This limit will be reduced to 0.50% on and after 01 January 2020.

Regulation 4 brings the confusion

So why do we have so much of confusion around this change.

Well, whenever we have choices we would have confusion.

For example, I want to upgrade my apple watch to series 4 released a few days back, but I am confused.

I am confused because there is Aluminium case version and there is a stainless steel version. And then there are color options in each of these versions.

Whenever we have a choice, we will have confusion about the better option for us.

For compliance with the requirements of SOx emission, the confusion is created by the regulation 4 that allows the alternative.

Here is what regulation 4 of Marpol Annex VI states:

The Administration of a Party may allow any fitting, material, appliance or apparatus to be fitted in a ship or other procedures, alternative fuel oils, or compliance methods used as an alternative to that required by this Annex if such fitting, material, appliance or apparatus or other procedures, alternative fuel oils, or compliance methods are at least as effective in terms of emissions reductions as that required by this Annex, including any of the standards set forth in regulations 13 and 14.

What are the Alternatives?

Regulation 4 allows the use of alternatives for complying with regulation 13 and 14.

So let us understand the available alternatives with respect to compliance with SOx requirements.

Broadly there are three options.

- Use of fuel containing less than 0.50% m/m of sulphur

- Use of alternative fuel such as LNG

- Use of exhaust gas cleaning system (also commonly called scrubber)

Let us understand each of these options.

Use of fuel containing less than 0.50% m/m of sulphur

This is probably the easiest option.

Easiest because this option hardly requires any modification on the ships.

Ship owners just need to make sure that fuel of less than 0.50% m/m sulphur is supplied to the ships.

But that is where the challenge lies.

Challenge 1: Fuel Availability

Few ship owners are worried about the availability of the low sulphur fuel. They have valid reasons for that.

As per Robin Meech, the demand for the MDO fuel with sulphur content less than 0.50% m/m will increase drastically post 2020.

And there are concerns about how much of this demand can be fulfilled by the bunker suppliers.

IMO is actively working on to resolve this issue.

As an initial step, IMO has urged all the states that are party to Marpol Annex VI to report the availability of 2020 compliant fuels.

But estimating the future fuel availability will be anything but easy for anyone.

Challenge 2: Costs

As the demand for fuel with less than 0.50% m/m would increase after 2020, the price for this fuel may increase too.

Ship owners need to take into account this factor while deciding their approach to handle the approaching change in MARPOL Annex VI.

Challenge 3: Fuel quality

While the Ultra-low sulphur fuel oil is good for the environment, it has its own operational challenges.

If the desired sulphur content is achieved by mixing of two different types of fuel oils, the resultant fuel though low on sulphur content may be unstable.

The use of unstable fuel oil may lead to clogged filters, damage to piston, piston rings and cylinder liners to name a few.

Low sulphur fuels offer less lubricity. Crew need to be aware of this and may need additional precautions to deal with it.

Low sulphur fuel could also have a higher amount of cat fines. This would expose the engine for damages if specific precautions for higher cat fines are not taken.

Use of alternative fuels such as LNG

LNG as a marine fuel is considered to be the future of the maritime industry.

There are two factors that make LNG an attractive option for marine fuel.

One, because LNG complies with the SOx requirements of the Marpol Annex VI, both global and in ECA.

And second, because LNG is considered a low-cost fuel.

Also since LNG is a cleaner fuel, the engines using LNG as fuel would require less maintenance compared to other fuels.

However, at present, there are two major drawbacks with the LNG fuel.

- The availability of LNG fuel and

- The lacking skills & knowledge of the stakeholders for LNG bunkering.

Availability of LNG has been a major concern for ship owners.

So ship’s operation area and routes and availability of LNG in these areas need to be considered when deciding to choose LNG as a marine fuel.

Furthermore, LNG bunkering and use of LNG as fuel is still a newer concept and not many seafarers have used this system.

This adds complexity and demands need for well-trained crew for handling LNG as fuel.

But the situation is improving in favor of LNG fuel.

It is expected that the number of LNG bunkering vessels would double by 2020.

As per MPA Singapore, Singapore will be ready for 2020 as it has expanded LNG bunkering group.

Use of the Exhaust gas cleaning system

This is probably the most debated option for compliance with the IMO 2020 SOx requirements.

With this option, the vessel continues to use the high sulphur fuel and an exhaust gas cleaning system fitted on board cleans the exhaust gas to reduce the SOx and CO2 emissions.

The compliance with using low sulpher fuel is easy. We just need to use the fuel with the desired minimum sulpher content.

But there needs to be a way to ensure compliance when we are not concerned about the actual sulpher content but with the sulpher content in the gases being emitted.

So how does it ensure compliance?

IMO has provided the values to measure in the cleaned exhaust gas to demonstrate the compliance with SOx emissions as per Marpol Annex VI.

The compliance is demonstrated on the basis of SO2(PPM) / CO2 (%v/v) ratio values.

So the scrubbers fitted on board for compliance with SOx requirements need to achieve these values.

But still, the question remains unanswered.

How do ship staff demonstrate compliance with scrubber fitted on board?

Resolution MEPC 259(68) provides complete guidance on this subject.

And there are two methods.

- Scheme A

- Scheme B

These two methods are quite similar to how the ship staff demonstrates the compliance with NOx criteria of the Marpol Annex VI.

Under Scheme A it is assumed that if the scrubber unit is fitted and maintained as per the maker’s guidelines, it would continue to comply with the initial test values.

So under scheme A, the compliance is based on verifying that the EGC unit is maintained in accordance with the guidelines provided.

Under scheme B, the actual measurement of gases being emitted is done.

But that is not all.

Ship staff also need to provide documentary evidence to demonstrate compliance with Marpol Annex VI in case scrubbers is fitted onboard.

These documents are

- SECP: SOx emission Compliance plan

- SECC: SOx emission compliance certificate

- ETM: EGC system technical manual

- OMM: Onboard monitoring Manual

- ERB: EGC record Book (or electronic logging system)

1.SECC: SOx emission compliance certificate

The scrubber manufacturer will provide the emission values that the scrubber unit will be able to achieve with the fuel of different sulphur content.

Off course these values need to be such that compliance with the requirements under Marpol Annex VI.

These values need to be certified and approved by the flag state.

Each scrubber (EGC) unit meeting the requirements will be issued with a certificate called SECC (SOx emission compliance certificate).

Ship staff needs to make sure that this certificate is available onboard.

Usually, classification society will certify these units on behalf of the flag states.

2. SECP: SOx emission Compliance plan

If the ship uses scrubbers for the compliance with Marpol Annex VI, the ship needs to be provided with SOx emission Compliance plan.

SECP need to be approved by the flag state of the ship.

SECP will provide

- the complete details of the EGC unit fitted onboard

- Instructions to ensure compliance with Marpol Annex VI with the use of EGC unit

- Details of all the equipments that the EGC unit is connected to or not connected to.

The approved SOx emission Compliance plan need to be onboard the vessels fitted with a scrubber unit.

3. ETM: EGC system technical manual

As the name suggests, this manual contains all the technical information about the EGC unit fitted on board.

At the minimum, the ETM would include

- The identification of the EGC unit

- The operating limits, or range of operating values for which the unit is certified

- Any requirement or restrictions applicable to the EGC unit

- Corrective actions of EGC unit does not operate as desired

The EGC technical manual need to be approved by the flag state of the vessel.

4. OMM: Onboard monitoring Manual

Onboard monitoring manual provides the details of all the sensors fitted in the EGC unit that is used to evaluate the performance of EGC unit.

The monitoring manual provides

- the position of such sensors or points from where the measurements are being taken

- The service, maintenance and calibration requirements of these sensors

- Calibration procedures for these sensors

- Any other data or information for the correct functioning of the sensors and system.

The onboard monitoring manual also needs to be approved by the flag state of the vessel.

5. ERB: EGC record Book (or electronic logging system)

We have already discussed scheme A and scheme B for demonstrating compliance.

Under scheme A, the scrubber unit is considered to be complying if it is maintained as per the manufacturer’s guidelines.

One important element in such a method of compliance is that any spare replacement needs to be done with the exact same type of spare.

In other words, the spare that would require replacement need to be replaced by same spare and not any other alternatives.

To ensure that an EGC record book needs to be maintained where all the details of spare replacement and maintenance on EGC unit need to be recorded.

Under scheme B, the direct measurement of emission gases is done.

In this case, EGC record book needs to be used to record the daily spot checks of the parameters listed in the technical manual.

Pros and cons for Exhaust gas cleaning system

One thing that attracts the shipowners for use of exhaust gas cleaning system is that the ships fitted with EGCS can continue to use high sulphur fuel oil.

This fuel is available worldwide and will continue to be so. This means that ship owners do not need to worry about the availability of fuel.

But this option too has some challenges.

Challenge 1: Fitting of exhaust gas cleaning system

For the new ships, it may be easier for the shipowners to design and then build the ships with EGC system installed.

But it may not be easy to retrofit the EGC unit on older ships.

The first challenge is to find the space in the engine room for the fitting of the exhaust gas cleaning system.

Challenge 2: Cost-effectiveness

The cost-effectiveness of the scrubber system depends upon the price difference between the HSFO and LSFO.

The estimated cost of retrofitting an exhaust gas cleaning system could be between USD 2-10 million depending upon the size of the ship.

These costs would only be justified if there is a significant price difference between HSFO and LSFO.

But what if in the future the price difference between these two fuel types is minimal.

That is where the challenge lies for the shipowners.

Predicting the cost-effectiveness of the EGC system is a challenge for the ship owners.

While making a decision about fitting an exhaust gas cleaning system for 2020 sulphur compliance, ship owners need to take a call on its cost-effectiveness.

Many ships are choosing scrubbers for IMO 2020 compliance.

As of 31 May 2018, 983 vessels have been installed with an exhaust gas cleaning system.

A study by IMO has found that EGCs will be cost effective for the majority of the ships with engines over 20MW.

The same study found that below 5MW, EGCs are often only cost-effective for new buildings, if at all, at the assumed fuel prices.

So far so that the Odfjell believes that the scrubbers don’t make sense for IMO 2020 compliance.

Conclusion

IMO 2020 is the buzzword these days.

Every shipowner is trying to devise a strategy to deal with the new SOx requirements that will be effective from 01st January 2020 which is not far.

And broadly there are three options that they need to choose from.

- Use of low sulphur fuel

- Use of alternate fuel such as LNG, and

- fitting of exhaust gas cleaning system (also call scrubbers)

Each option has its own pros and cons.

While the Low sulphur fuel is expensive, it would require any changes in existing ship’s equipments.

LNG fuel could save shipowners some money but its availability remains a concern at least for now. Moreover, the expertise in handling LNG fuel and its bunkering is still lacking.

Fitting of exhaust gas cleaning unit allows to continue use of HSFO but retro-fitting this on existing ships would be a challenge.

Moreover, its cost-effectiveness needs to be considered as it would mainly depend upon the price difference between HSFO and LSFO.

Different shipowners would prefer different options depending upon the trade of their vessels.

For example, as per Maersk CEO, Low Sulphur Fuel is the best solution for 2020 sulphur cap.

And as per Robin Meech, A third of total bunkers in 2025 may be high sulfur fuel oil being scrubbed.

It remains to be seen how shipowners would respond to this fast approaching challenge.

Share this:

About Capt Rajeev Jassal

Capt. Rajeev Jassal has sailed for over 24 years mainly on crude oil, product and chemical tankers. He holds MBA in shipping & Logistics degree from London. He has done extensive research on quantitatively measuring Safety culture onboard and safety climate ashore which he believes is the most important element for safer shipping.

Search Blog

26 Comments

Sir, Very much informative appreciate in tons

Thanks Rana...

Thank you captain , I am very satisfied with the article but could you please inform the Sulphur percentage for ECAs from 1st Jan 2020

In ECA ships continued today use fuel with maximum sulphur content 0.10% m/m as is being done since 01st Jan 2015. There is no change in that post 01st Jan 2020.

vry well xplained sir. What will be sox content in SECA after 2020

In ECA ships continued today use fuel with maximum sulphur content 0.10% m/m as is being done since 01st Jan 2015. There is no change in that post 01st Jan 2020.

Thank you for a very clear explanation. Reading your blogs will be part of my Daily Routine. All the best to you and your team.

Thanks Malon...

How I wish that books were written in such a comprehensive yet simple manner.Thanx a ton for all the blogs here sir.

Thanks Alok...

Thank you aloooot VGP please and all requirement of visiting USWater

Thanks Waleed.. will write on VGP...

Excellent article. Very well explained. Loved it

Glad you liked it Rajesh...

Thank you very much sir for clear and easy explaination of the subject. A great help.

Excellent article . Very well explained . Kudos to you and your team for all the efforts .

Thank you sir, I am preparing for ASM... Your site is really helpful

Well informative. LSHFO availability & what viscosity ?

Information well presented and a great guide to Chief Engineers!

Thank you and such well explained. Great job.

great article sir......we are more greedy now...want more and more articles .....

I was thrown out of my own house was sleeping in a hotel for weeks she also took possession of my son could only see him once a week then I found out she was in love with my accountant all these while so I went online and I came across a Russian private investigator who help me get all my properties and my accounts back even my company back how he did these I don’t know but I gave all the information he asked for and followed all his instructions and now I’m happy my life’s better now. Thanks to HACKINTECHNOLOGY@CYBERSERVICES.COM I just said I should share my own story here Thank you

According to Value Market Research, the latest technology trends and global market opportunity analysis in the LNG Bunkering Market industry growing with a high CAGR in the upcoming year. Our report has categorized the market based on technology, service, development, vertical and region. https://www.valuemarketresearch.com/report/lng-bunkering-market

Dear Sir, thank you for your valuable guidance. is always helping us to understand the new regulations in simple way. Please write blog on EEXI....

Leave Comment

More things to do on myseatime

MySeaTime Blogs

Learn the difficult concepts of sailing described in a easy and story-telling way. These detailed and well researched articles provides value reading for all ranks.

Seafarers Question Answers

Ask or answer a question on this forum. Knowledge dies if it remains in our head. Share your knowledge by writing answers to the question

MySeaTime Podcast

This podcast on the maritime matters will provide value to the listeners. Short, crisp and full of value. Stay tuned for this section.

Excellent explanations. Cleared many doubts reg. 2020 sulphur cap. Thank you.

Glad you found it useful Murugadasan...