There is no single fail-proof method to get your tanks cleaned to methanol standard after Vegetable oil. Sorry!!!

I wish if I could tell you that if you did this particular thing your tanks will be ready for methanol standard.

But it just doesn’t happen that way.

The reality is that you can’t rely on one technique to clean your tanks after Vegetable oil.

You have to approach it using a combination of different strategies.

But positive thing is that there are few principles that we need to follow to make the tank cleaning much easier and less troublesome.

Let us discuss.

Type of Vegetable oil

The first and foremost, we must know the type of palm oil that we had in the tanks. This is important because the tank cleaning method would depend on that.

If we make a mistake in this, we can never be able to clean the tanks to methanol standard. Never!!!

So here is the type of palm oils that I am referring to.

- Dry

- Semi-dry

- Non-dry

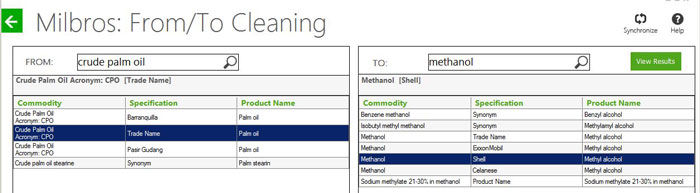

The question is, how to find which category palm oil loaded on your vessel falls into. Tank cleaning software (provided on board by of the chemical tanker operators) helps in that.

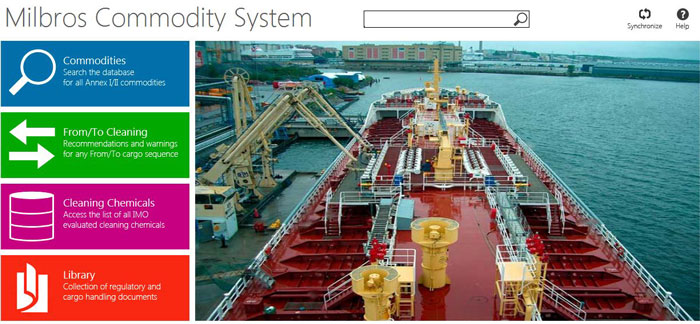

Milbros is one of such software. Let us say we just discharged following Vegetable oils

- Sunflower oil

- Crude palm oil

- Palm Stearin

And we want to check the type of Veg oil for “Sunflower oil”. Open Milbros on the computer.

It will lead you to the initial screen.

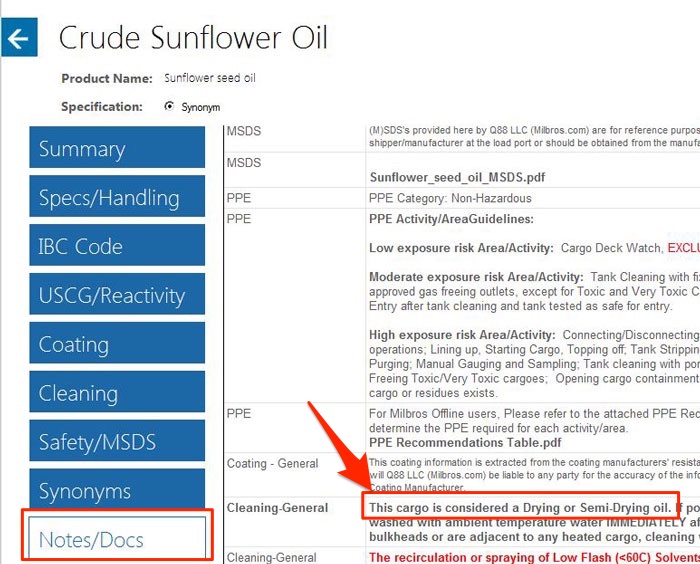

In the search option, type Sunflower oil and choose sunflower oil from the options.

In the sunflower oil screen, go to notes and under Cleaning, look for any information of describing sunflower oil as drying or Semi-drying oil.

As you can see, Sunflower oil, in fact, a drying or Semi-drying oil.

This information can also be found in other resources like Dr. Verwey’s tank cleaning guide.

Precaution with drying and Semi-Drying palm oils

Now, why is it so important to know if the palm oil is drying or Semi-drying type?

The drying and semi-drying oils get to harden when it comes in contact with air.

If allowed to come in direct contact with air, these palm oils would dry quickly and become hardened on the tank coating. There are few conditions in which these oils can dry on the coating.

- If there is no moisture in the tank and/or

- If there is the high temperature in the tank.

Why high temperature? Because higher temperature absorbs the moisture from the atmosphere. This is particularly important while washing the tanks containing drying or semi-drying palm oils.

We must initially wash these tanks with ambient seawater. If we use hot sea water, the palm oil will become hardened on the coating and it will not be possible to remove this from the coating.

Another important point is to wash these tanks as soon as discharging is completed and empty tank certificate issued by the surveyor. If the terminal does not allow tank cleaning at berth, we can just introduce some water in the tank and recirculate it for few seconds in every few hours to keep the tank bulkheads moist.

This may look to be a small step but it really helps in a big way.

Take-away points for drying/Semi-drying palm oils:

- Initially wash the tanks containing drying or semi-drying palm oils with ambient seawater (or fresh water) for 1-1.5 hours.

- Keep the tank moist till the time tank cleaning is commenced.

General tank cleaning procedure

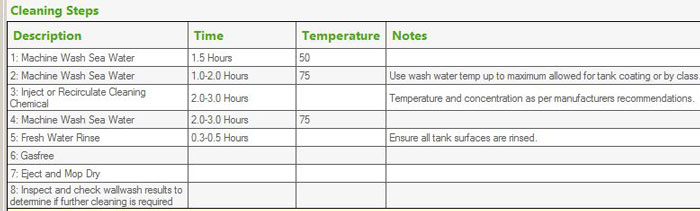

There are tons of resources to advise the general procedure to follow for cleaning the tank after a cargo. As discussed Milbros is one of these resources.

In the Milbros software, go to “From/to cleaning” section.

Enter the “from and to” cargoes and click on “View Results”.

This will show you the recommended cleaning, step by step.

Now if you follow these steps exactly as it is, there is no guarantee that your tanks will be ready to wall wash standard.

You may have to clean for an extended period (2-3 hrs mentioned in these steps may not be enough). Usually, 4 hours washing cycle is considered to be sufficient.

Main principles of tank cleaning

There are a number of tank cleaning chemicals that we may use during tank cleaning but the use of these chemicals helps only to a certain extent.

There are somethings other than the use of chemicals that brings wonder results for the tank cleaning.

An efficient cleaning of tanks require

- Physical Cleaning of the tanks

- Chemical cleaning of the tanks

Physical cleaning of the tank

Remember in old time (and in some places, even today) how the clothes are washed manually.

Yes, mainly by use of force.

More force, better cleaning. Though damage to the clothes needs to be kept in mind when using too excessive force.

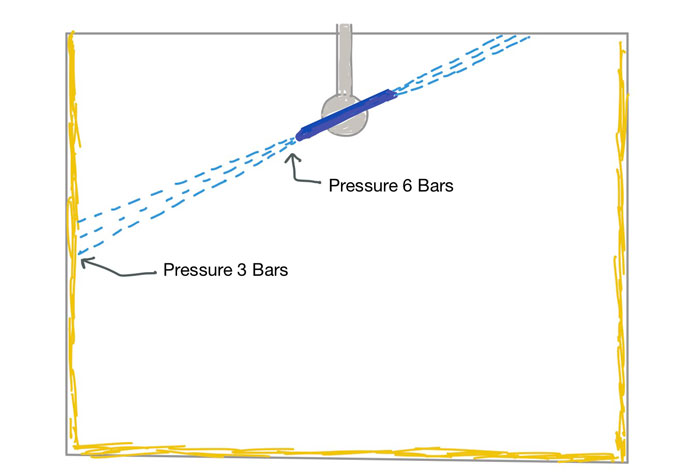

Same applies to the tank cleaning on chemical tankers. The pressure of tank cleaning water is very important for efficient cleaning.

Washing of the tanks at 6 bars pressure will achieve nothing. More pressure the better.

Usually, 8 to 10 bars is considered to be good pressure, 8 Bars being the minimum. If our system allows, we must try to achieve at least 9 bars pressure in the tank cleaning line.

This is because of the fact that pressure in tank cleaning line and at the tip of the tank cleaning machine will not be same as the pressure that hits the bulkheads.

Take-away points: Higher the pressure of the tank cleaning medium, better will be the cleaning. Reduce the number of tanks being washed if pressure is less.

Chemical cleaning of tanks

When I say, cleaning of the tanks chemically, I do not mean the use of chemicals. There is something else more important than using chemicals for cleaning.

That is temperature. Yes, the temperature is the best chemical you will have during tank cleaning.

More the temperature of the cleaning medium better will be the cleaning.

Allow me to explain with the same analogy of washing of clothes. Dip a similar dirty shirt in cold water and in hot water buckets and leave it there for few hours.

After few hours when we take out the shirts, water in which of the bucket you would expect to be cleaner?

Of course, the cold water will be cleaner as hot water would have taken more dirt out of the shirt. But how?

This is the chemical reaction I am talking about here.

When I talked about the pressure, I talked about the pressure at which the water hits the bulkhead and not the pressure at the nozzle tip or in the tank cleaning line.

Same applies to the temperature.

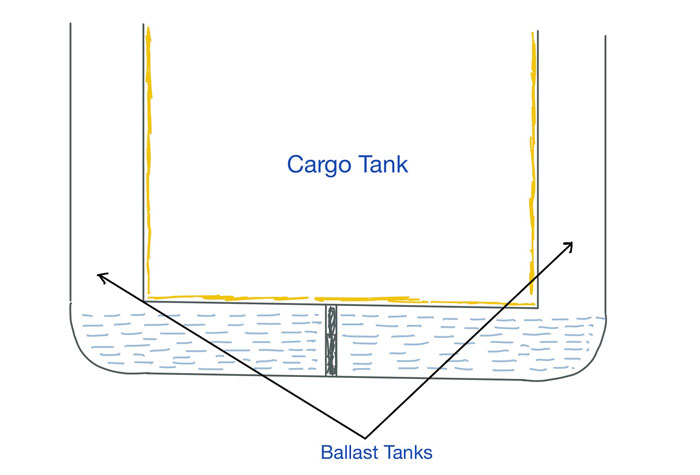

If the bulkhead itself is cold or has the ballast on the other side of the bulkhead, the cleaning will not be effective.

I totally agree that removing the ballast from the adjacent ballast tanks is a real pain but believe me when I say it. Gains in terms of effectiveness of the cleaning outshines the pain of removing the ballast.

So we must lower the ballast water level from the adjacent tanks to a level where the water is not touching any of the cargo tank bulkheads.

But the use of higher temperatures is not true every time. There are some exceptions to this like the initial washing of drying and semi-drying palm oils (More exceptions later in this blog).

Take-away points: Barring few exceptions, higher the temperature, better will be the cleaning.

Use of chemicals

While high pressure and higher temperatures will do most of the job, cleaning to wall wash standard would still most likely require the use of chemical re-circulation in the tanks.

And the question is which chemical to use?

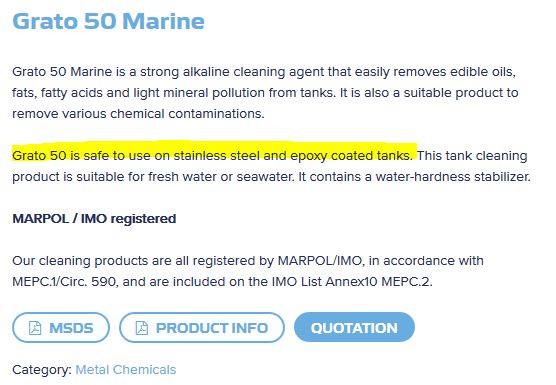

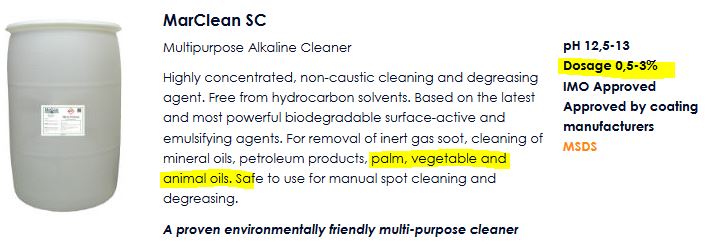

The first condition for choosing the tank cleaning chemical is that chemicals need to be IMO Approved. MEPC circular list all the chemicals with their makers that are approved for use by IMO.

Check if the chemical you have planned to use are in this list.

The second condition is that the chemicals need to be safe to use with respect to the tank coating. This information can be found from the information provided by the chemical maker.

Even when these conditions are satisfied, we still need to choose from the number of chemicals available in the market. And which chemicals work best will usually come by the experience of tank cleaning.

Generally, any of these chemicals are good for cleaning the palm oil tanks

- Grato 50 (for stainless steel tanks) and Grato 14 (for Zinc/Epoxy coated tanks) Make: CP Metal Chemicals

- Marclean SC or Marclean AC+ Make: Teca

- Caretank Eco Make: Marine Care

These are the chemical to do the main wash which is to make the tanks clean in all respects. But apart from these chemicals, you may need to have few other chemicals too just in case you.

You may need to have chemicals to remove odor from the tanks or color from the samples.

Well, some companies do not give many options to choose from and they have fixed chemicals to choose from and have the recommended list and quantities of the chemicals to maintain on board.

This may in a way remove some load from the chief officer.

We also need to have an estimate of what quantity of the chemicals would be required for tank cleaning. This can easily be calculated from the concentration of chemical required in the chemical solution and minimum volume of solution required for the pump to take suction during re-circulation.

For example, 0.5% of Caretank Eco is recommended for re-circulation. Let us say 3 m3 (3000 liters) of water is required for the pump to maintain good pressure during the re-circulation.

Then the quantity of Caretank Eco for one tank would be 3000 x 0.5/100 = 15 Liters.

Chemical Re-circulation

For the chemical re-circulation to be effective, there is this one pre-condition.

The initial cleaning needs to be effective. This means that there should not be any traces of previous cargo in the tank. The tanks need to be absolutely clean visually. And higher temperature/Higher pressure during initial cleaning really helps in that.

The higher temperature-better cleaning is applicable to the chemical re-circulation also but there are few points that we need to keep in mind.

1. Caustic based chemicals can make your tanks white if heated to higher temperatures.

If caustic based chemicals are used for re-circulation, we need to be careful with heating the solution.

The temperature of the cleaning solution should not be increased to more than 40 C.

It is also recommended to not heat the solution at all but sometimes it is unavoidable especially when cleaning in a low-temperature environment.

2. Using fresh water for making the cleaning solution

If you need to heat the chemical solution used for recirculation, be aware of what water you will use to make the chemical solution.

If you use sea water and keep the steam in heating coils on, there are chances of hard solid salt deposits on the entire heating coils of the tanks.

This salt deposits could become difficult to remove.

We can just use the fresh water to make the chemical solution to avoid any of these solutions.

But sometimes we are short of fresh water and we need to use sea water for making the chemical solution.

In that case, there are few things you can do to avoid this.

First, stop the steam in the heating coils at least 30 minutes before stopping recirculation.

Second, rinse the tank with fresh water for 5-10 minutes immediately after chemical recirculation.

Keeping tank coating in mind

More temperature more pressure is good for removing the impurities and better cleaning of the tanks.

But it may not be so good for the tank coating.

The vessel must be aware of the maximum temperature allowed by the tank coating manufacturer.

Usually, coating manufacturer will have some temperature limitation but these limitations are for the temperature of the cargo.

Exposure to higher temperatures for short period is usually allowed and that does not affect the tank coating.

In any case, the tank coating manufacturer must be consulted to have the clarity on the use of higher temperatures than specified for tank cleaning.

Conclusion

Cleaning of the cargo tanks with palm oil as previous cargo is a difficult task.

And if you have to clean these tanks to load wall wash cargo, the task becomes even more difficult.

But this difficult task can become easy to a great extent if few simple principles of tank cleaning are followed.

More pressure and more temperatures (barring few exceptions) are one of such principle.

Choosing the correct chemical for cleaning and following the instructions for the chemicals to be effective also helps.

Share this:

About Capt Rajeev Jassal

Capt. Rajeev Jassal has sailed for over 24 years mainly on crude oil, product and chemical tankers. He holds MBA in shipping & Logistics degree from London. He has done extensive research on quantitatively measuring Safety culture onboard and safety climate ashore which he believes is the most important element for safer shipping.

Search Blog

52 Comments

Thanks alot for this excellent article. It reminded me my last tank cleaning..sir I have a doubt regarding the concept of temperature..it's found that better cleaning is obtained at a high temperature.....but what about the coating condition...last vessel we had epoxy and as per manual we should exceed the ambient temperature..... Another thing we observed was tank was cleaned after using caretaker eco...but in wall wash samples we obtained white bubbles which took almost 30mins to settle

I have added a para regarding coating after your comment. Regarding your comment about caretank eco, it could usually be because of traces of chemical left on the coating. More washing with clean water usually helps. Steaming of the tanks is another option.

Very helpful topic frm Capt. Rajeev as always! I'm a regular reader of your blog capt and I learned a lot. Thank you, looking forward for more topics esp. w/ regards to Chem Tanker operations! More power.

Thank you Jec....

Informative and well written. I noted you mentioned use of sea water for recirculation with Alkaline cleaner. This is not a good solution as the seawater will neutralize the Alkaline. And ctc is far better than careclean eco

Agree with your points. As I mentioned, sometime there is no option but to use sea water because of less FW ROB. All chemicals of CP metal including CTC are far better than many of the other chemicals but these are expensive too and thus many ship owners do not provide that.

Rightly said Sir. However, some chemicals (like KT Plus and Atlas 202 which are heavy duty alkaline cleaners and Potassium Hydroxide based ) have metasilicates, which is a water softening agent. Hence it can also be used with SW, as opposed to Caustic based (which should be used in FW) and can potentially leave whitish powdery residues. To assist the use of chemical cleaning agents, we should consider adding Sodium Carbonate as a water softener. This will also help in preventing hardness compounds forming and remaining on the bulkheads. Best results are achieved by using chemicals that Saponify the remaining oils. Usage of Potassium Hydroxide based Chemicals, (such as; Either Atlas 202 at 3% OR Careclean Alkaline at 3% OR Starmarine (POT) at 3% - or other Potassium Hydroxide based chems) can be assisted by using a neutral HCF detergent, such as; Teepol at 0.5% OR Careclean Neutral HCF at 0.5% OR Starmarine Neutral HCF at 0.5% or other equivalent, neutral non-hydrocarbon based chemical. The neutral detergent will assist in emulsification and thus boost the cleaning action of the Alkaline cleaner.

Comprehensive article. Many minor points have been addressed. It's useful for palms to cpp also.

Very good article by Capt Rajeev in a very simplied manner. Have been through the other blogs by Capt Jassal highlighting the finer points. Request if you can also put a blog about tank cleaning on crude oil tankers especially w.r.t. The use of slops. Concept of primary and secondary slops, procedure for taking in water and amount of water to be taken. Have seen your blog about odme, very well written. Would be eagerly waiting for this blog. Thank you

The guidelines do not account for the degree of solubility, treating completely soluble products and those that are partly or even just slightly soluble all in the same way. The only distinction made is between soluble and non-soluble products, but this factor should also be taken into consideration when planning the cleaning method. house cleaning services nj :)

Dear Capt. Rajeev, First of all we would like to share our compliments regarding your blog. The information is very valuable for everyone who is involved in tank cleaning operations. As a supplier we regularly notice that our products are known as expensive. However, we would like to put this assumption in a bit more perspective. When people are talking about price, they often only look at a price per litre. It is at least as important to consider what amount of product is required per cleaning and what the use of this product means for the duration of the total cleaning process. At CP Metal Chemicals & Henkel we strive to develop products that are of such quality that a lower concentration is required and the total cleaning time can be reduced. Bottom line, when you are looking for the most economical solution for your tank cleaning challenge it is important to take the required quantity of the product and its effect on the total cleaning time into account. Of course we would be honoured to invite you over for a visit to our company and explain everything about our products and philosophy, supported by actual figures and dates.

Hi Kelly... I have cleaned the tanks with CP Metal Chemicals and these are the best available so far in the industry. I do get your point and I completely agree with you. CTC-VLC cleaner is required only in the concertration of 0.2% of the solution volume. But as you said it is wrongly perceived by the Ship owners that CP Metal Chemicals are expensive. May be you need work on changing this (wrong) perception.

Thank you for your reaction Rajeev. The team and I do everything we can to change this perception and pointing out the importance of looking at the overall picture. Anyway, we would like to wish you all the best and we are looking forward to your next article!

Dear sir, Can u please explain how to calculate amount of water required for tank cleaning on a product tanker for change of grade.

Good read. Helps people to get an insight on the tank cleaning aspects. How do you calculate the amount of water to use for re-circulation and the %age of chemical to add? Is it based on tank size? If a cleaning is required for a change from Gasoil to Clean chemicals on a MR tanker, what is the cleaning recommended?

The amount of water required for recirculation depends on the Pump efficiency. If you are recirculating in the same tank (using Octopus flange, etc.) you would like to have sufficient water for suction, but at the same time, you dont want the tank top to be covered with water which will hamper the Machine effect in the bottom. If you are doing recirculation from Slop tank, then you are not worried about that. For deciding the Cleaning chemical %, always refer the Product Data Sheet. Every time, refer PSD of any chemcial for its usage. A perfect example - Bleach recirculation should not be carried out for more than 1.5 hours. Because after that, it is not effective and you are just recirculating water in the tank. For cleaning from Gasoil to Clean Chemicals, you should consider the type of coating, next cargo requirement (wall wash grade or water white grade), Soot deposits, No active Rusting, etc. For detailed professional cleaning services, you may contact us on www.vikingmarines.com . Thanks.

Hi mates first of all CTC will not work a lot for veg cargoes after methanol . We need alkaline based detergant first of all . Like unitor alkeen safety or Aquabreak .First try direct injection method rather than circulatuon will take a lot of time .of course after hotwash then u need to make manual spray bleach 10 - 12 % diluted it till cargo tank ph restriction for zinc coating max ph 10 for example . Then flush it with sw around 1 hour then apply fw . Then check the ph of coating with ph strips after bleach should be max 8 . Then apply di water spray . If you make circulation with alkaline based detergants u can find the heating coils and some walls with white powder so u need to use rust remover direct injection . Of course circulation method than direction injection but if u have lots of tie . So try one tank direct imjection and spray bleach if it works do not waste for circulation Never use CTC for veg cargoes . I do not recommend Ctc like water based detergants . Better order alkaline and solvent based detergangs like degreaser never use water based detergants .best regards

great article for tank cleaning process. good to read your information. Visit us here for offshore chemical tank manufacturers

excellent article. great to read your article thanks for posting Visit us here for offshore chemical tank manufacturers

What a nice article ! I also troed to make a video !! Please Watch below video of framo pump purging https://youtu.be/laedqAEIQXw

What a nice article ! I also troed to make a video !! Please Watch below video of framo pump purging https://youtu.be/laedqAEIQXw

Very good article and gives benefits concerning tank clean.But as an experienced Chief Officer I strongly recommend to perform the cleaning operations in two steps ; first clean the tanks for WW standard, and after clean the tanks to methanol standard. I believe that how water will remove all the residues from the tanks so the last thing to do will be cleaning the tanks to methanol standard. If you apply cleaning agent early and wıthout removing the residues, the cleaning agent and cargo residues may react each other and end up with serious problems. The best cleaning agent in how water at good pressure. Once a time, I did that mistake and result the residues reacted with the detergent leaving white deposits on wall and lines .Please also consider this advice.

Sir, Can you advise how u managed to remove the white deposits, Self having same issue

Dear Capt Rajeev I am following yr blog here and do appreciate indeed how its is done. My new job what I started recently requires good knowledge of chemicals tankers... so I am trying to learn as much as possible fm open sources. If speaking of cleaning fm FAME to Methanol and apart of standard Milbros cleaning instruction are there anything specific tips you could advise ? mthks in advance brgds/Leonid

http://khanjeewatertankcleaning.com/

Hi captain , please tell me is it hard to perform tank cleaning from nitric acid to methanol, do we need to make purging after tank cleaning , what ph level should be and how to check it, what is neutral environment in the tank ? Can you write me on e-mail , I want to ask you some more questions , because I need to pass interview with superintendant

Thank you for sharing this useful information, This blog is really good and the information is also well provided. I read like this article and I gain more information.http://servicewaala.in/Pages/Cleaning.aspx

we have a nitric acid tank, is it possible to store / replace by food grade soybean oil. if possible , please suggest us the procedure and code of practice of this storage transformation.

we have a nitric acid tank, is it possible to store / replace by food grade soybean oil. if possible , please suggest us the procedure and code of practice of this storage transformation. mail: faisalcuet@gmail.com

Nice Information. Thanks for sharing. Connexion Engineering can maintain generators for essential services such as hospitals, ambulance stations and other essential services like data centres, Defence and commercial buildings. We service and maintain the emergency generators and their related fuel systems, including tank cleaning and fuel filtering, tank integrity testing , upgrades and continuous improvements for enhanced safety and compliance with relevant standards. #tank_cleaning #tank_inspections #fuel_system Tank Service

Dear Capt Rajeev, Thanks very much for the detailed tank cleaning blog. Very informational!. I have a question of tank cleaning after carriage of soyabean oil. We are loading/discharging SBO on barges that are non-coated tanks. We load the same soybean oil in the same tanks, but after every discharge, at least 5 barrels of thick oil residue is squeegeed. The barge owners are suggesting to wash the tanks with FW, but I am hesitant as we are loading the same cargo and quality is not an issue. also, I understand SBO is sensitive to water and tanks will need to be dried. Any advise would be appreciated. P.S - we plan to use cutter stock or Diesel, to clean the barges before redelivering back to owners.

Dear Capt Rajeev, Thanks very much for the detailed tank cleaning blog. Very informational!. I have a question of tank cleaning after carriage of soyabean oil. We are loading/discharging SBO on barges that are non-coated tanks. We load the same soybean oil in the same tanks, but after every discharge, at least 5 barrels of thick oil residue is squeegeed. The barge owners are suggesting to wash the tanks with FW, but I am hesitant as we are loading the same cargo and quality is not an issue. also, I understand SBO is sensitive to water and tanks will need to be dried. Any advise would be appreciated. P.S - we plan to use cutter stock or Diesel, to clean the barges before redelivering back to owners.

We have designed refuelling solutions for the transport sector compliant with all relevant Australian Standards. This includes refuelling for rail, mining vehicles, trucking industry and light vehicle refuelling facilities. Tank Cleaning

Decent article, your article has everything which I want. You have given a piece of useful information about the Tank Cleaning From Vegetable Oil. Cylinder Cleaner Brush for Sale.Excellent post. .

Excellent and informative article. You have good knowledge of the Tank Cleaning From Vegetable Oil. Your article has everything which I want. Cylinder Cleaner Brush for Sale.Good job.

According to Value Market Research, the latest technology trends and global market opportunity analysis in the Industrial Cleaning Agents Market industry growing with a high CAGR in the upcoming year. Our report has categorized the market based on technology, service, development, vertical and region. https://www.valuemarketresearch.com/report/industrial-cleaning-agents-market

That is some quite useful information you have provided here. When it comes to cleaning tanks, it is important to understand the safety regarding various equipment used for cleaning the water. Thank you very much for sharing this post here. After reading this, many people will get good ideas. Exterior Cleaning Services Tonbridge

Praise and thanks are many in our lives, but we rarely meet people who leave an impact on us, and we may be unable to thank them, but we do not deny their actions and do not forget their actions. I say thank you for this useful article with really valuable information.

I was reading your blog when I was 3rd off. , I was reading your blog When I was 2nd off. and I still reading your wonderful articles as I am a Chf off. ! Thank you for everything...

Thank you very much for your kind words, we are pleased it’s helpful for youhttps://balajichemsolutions.com/ways-to-choose-the-right-cleaning-and-conditioning-chemicals/

This is really what I was searching for. I am feeling joyful to came here. I would like to thank you for sharing such info with us, I like to advise you that Keep sharing such ideas in the future as well. Thanks & Regards Steam cleaning service in abu dhabi

Thanks for posting this info. I just want to let you know that I just check out your site and I find it very interesting and informative. I can't wait to read lots of your posts. Thanks & Regards Apartment steam cleaning in abu dhabi

Thanks for posting this info. I just want to let you know that I just check out your site and I find it very interesting and informative. I can't wait to read lots of your posts. Thanks & Regards Deep steam cleaning in abu dhabi

Hi, this is a great blog. You shared such a beneficial blog about cleaning the tank. You recommended to clean tank with vegetable oil and methanol. Thanks for sharing such a great and informative blog. Mason KrickBy crackpcsoft.net/

This post is extremely radiant. I extremely like this post. It is outstanding amongst other posts that I’ve read in quite a while. Much obliged for this better than average post. I truly value it!

Last cargo she carried in that tank was palm oil , so please advise the standard cleaning procedure to load base oil

Very informative article sir, I am about to be begin my career as choff can you please guide me about the maximum concentrations of tank cleaning chemical concentrations allowed during tank cleaning chemical. Kindly guide.

Your site always offers some really interesting information. Thank you for sharing it with us. Samsung service center in sharjah

I like your blog post. Keep on writing this type of great stuff. I'll make sure to follow up on your blog in the future. laptop repair near me

Leave Comment

More things to do on myseatime

MySeaTime Blogs

Learn the difficult concepts of sailing described in a easy and story-telling way. These detailed and well researched articles provides value reading for all ranks.

Seafarers Question Answers

Ask or answer a question on this forum. Knowledge dies if it remains in our head. Share your knowledge by writing answers to the question

MySeaTime Podcast

This podcast on the maritime matters will provide value to the listeners. Short, crisp and full of value. Stay tuned for this section.

Your articles are excellent, Capt. Rajeev. Very easy to understand. Waiting for more.

Glad you liked it Kulita...

Hy Captain, I am at the beginning of my career as a Chief mate and I like to gather information everywhere. I would definitely take some advice on washing sunflower oil as the next cargo will be MEG. I read the article you wrote and it looked very interesting. Thank you!