I earlier said, Life saving equipments are the best friends we have on board. And it is our responsibility to keep these in shape.

Each life saving equipment is our friend and we all agree that. But like in real friends we need to give “Life saving equipment” our time that it deserves.

How about saying a “Hello” to lifebuoy once every month. Or saying hello to lifeboat engine every week by testing it.

If we give our time to these appliances, these will remain our friends. If we do not, they will not. It is a simple give and take.

For example, Let me tell a short story of the times I was a 2nd mate.

The third mate told me, what can happen to a lifebuoy during its lifetime. These are there and we just need to check if these are in numbers that is required.

Few day after, during PSC inspection it was found that lifebuoys were too heavy. Lifebuoys had the sea water soaked into it through a plug that was supposed to be watertight.

You see how these friends can get angry !!

But can we keep these in shape if we do not know what is required to maintain these. Or what elements we need to check for life saving equipments.

This guide will deal with the inspections required on davit type lifeboats as well as the best way to conduct the inspection.

Let us start.

Life boat (except free fall lifeboats)

Lifeboat is the first thing that comes to mind when we talk about life saving appliances. But an empty lifeboat will be as bad as no lifeboat on ship. And defective equipments inside lifeboat will be as bad as an empty lifeboat.

Let us see what we need to do to ensure that lifeboat will be ready to help if required.

a) Checking the inventory

Frequency: Every month, Applicable to all ships

Ref: SOLAS Chapter III/20.7.2

As per SOLAS Chapter III/20.7.2, ship’s officer should check the inventory of the lifeboat equipment at least once every month. Most companies will have a checklist for this in their SMS manuals. Apart from physically checking the inventory, look for following

- Check that food ration packets are sealed and have vacuum.

- Check the expiry date of items like food ration, first aid kit, fresh water packets etc. Sometimes you will find the radar reflector with the expiry if it of cloth type.

- If one SART is placed in the lifeboat, check its operation with X-band radar.

b) Moving the lifeboat from the stowed position

Frequency: Every week, Applicable to all ships

Ref: SOLAS Chapter III/20.6.3

SOLAS require that at least every week the lifeboats should be moved from its stowed position.

Many PSC inspections findings report that many lifeboats would not move when winch brake is lifted. Most of the time reason for the lifeboat not moving is

- Frozen sheaves

- Davit arm stuck with the ship structure

- Harbor pin stuck because of rust, bent pin or because of it holding davit weight.

Whatever the reason, if we move the lifeboat from its stowed position every week ensures the lifeboat readiness.

c) Turning out from stowed position

Frequency: Every month, Applicable to all ships

Ref: SOLAS Chapter III / 20.7.1

We might get confused between moving from stowed position and turning out from stowed position. When we talk about moving out, we are required to move the lifeboat slightly. By turning out we need to lower the boat to the level where boat will be directly above water.

Usually this requirement is fulfilled during monthly lifeboat drill when we turn out the lifeboat from its stowed position.

d) Test run lifeboat engine

Frequency: Every week, Applicable to all ships

Ref: SOLAS Chapter III / 20.6.2 and MSC.1 / Circ 1206/Rev 1

A lifeboat is of no use if it cannot move away from a sinking ship. Or if it cannot move to the helping ship. We need to test the lifeboat engine every week.

But wait, what can happen to the lifeboat engine if we had tested it few months back ? You would be surprised to know that for the lifeboat related PSC deficiencies, more than 20% were for failing to start the lifeboat engine.

Remember, we need to say hello to all of our friends.

Coming back to the question !! What can happen to the lifeboat engine if we did not say hello every week by testing ?

- You may not realize that fuel tank is below the required level.

- You may not realize that starting batteries are either dead or are not charging. Or after the last lifeboat drill, someone forgot to connect the battery charger

- You may not realize that the engine is not starting in cold conditions.

All these points we can realize if we say hello to the lifeboat engine every week.

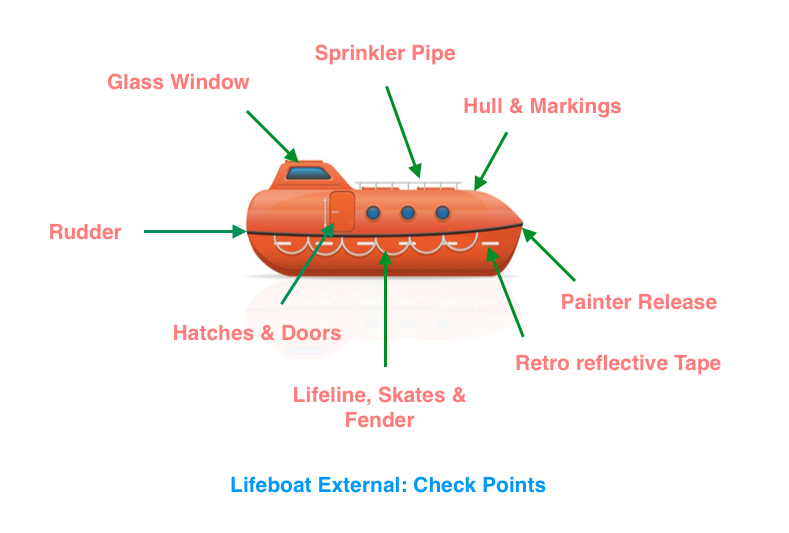

e) Visual inspection of lifeboat and launching appliances

There are few things that can only be inspected by naked eyes. No testing but just with the naked eyes. Visual inspection of the lifeboat aim to cover that.

While making visual inspection, look for

- any signs of lifeboat hull damage or cracks

- faded marking on the lifeboat

- Damages or old Retro-reflective tapes

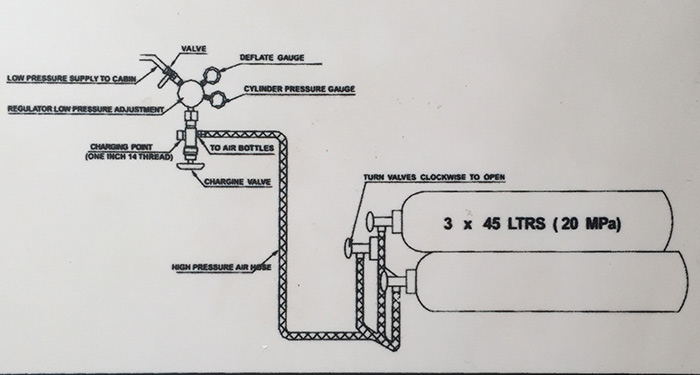

f) Self contained air support system

Applicable to: tankers

Ref: MSC.1/Circ.1206/Rev.1

Self contained air support system is used to maintain a positive pressure inside the boat. This prevents any toxic vapors to enter inside the lifeboat while abandoning the vessel in toxic environment.

Let us see what we need to do to make this friend happy.

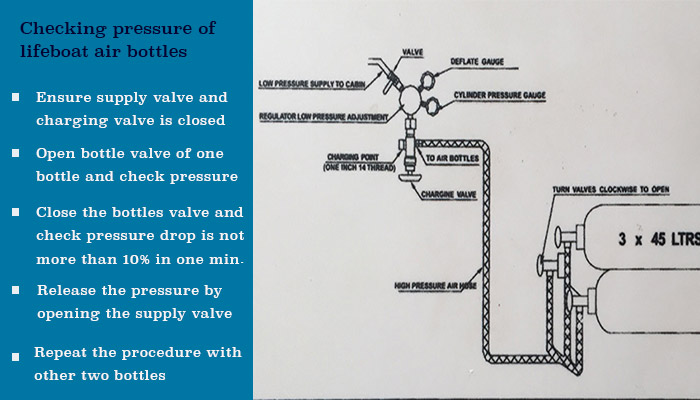

i) Monthly pressure check

We cannot use this system if the air bottles are empty. Every month we need to check if the air bottles are full. Upto 10% decrease in bottle pressure is allowed.

Most of the time there are three air bottles of around 45 Litres capacity.

After you have checked the pressure of one bottle, we must ensure that we release the pressure in the line before we check the pressure of other bottles.

ii) Annual inspection by Shore

Reference: MSC.1/Circ.1206/Rev.1

MSC circular require the lifeboat air bottles to be visually examined by a competent authority atleast every year. This inspection is limited to

- checking the external condition

- Checking the pressure of the air bottles

- Checking any Leakage the air line

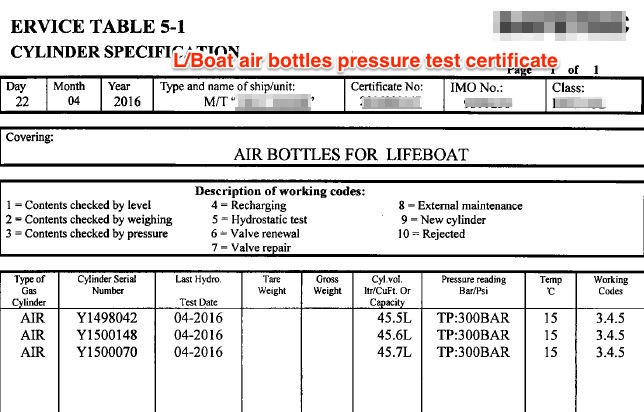

iii) Pressure testing of the air bottles

Ref: Class rules

Frequency: Every 5 year

While the pressure testing of the bottles is not a SOLAS requirement, but it required as per rules of Internaltion associated of classification societies.

Every 5 years (usually during 5 yearly dry docking of the vessel), the air bottles are taken ashore and pressure tested to 1.5 times the working pressure.

A certificate of pressure testing of life boat air bottles need to be on board.

g) Lifeboat sprinkler system

The sprinkler system is required on the lifeboats of all oil tankers. And the idea of lifeboat sprinkler is same as is with any sprinkler system. To distinguish the fire.

Lifeboat sprinkler system is used if the oil fire has enveloped the lifeboat. To ensure that lifeboat sprinkler system can work in emergency would require regular testing. Here is how we can ensure this.

Test Every 3 month by ship staff & yearly by the maker

Ref: MSC.1/Circ.1206/Rev.1

During every occasion of launching the lifeboat into the water, we must test the sprinkler system. The components to check are

- All the nozzles are open and not clogged.

- The Sprinkler pump is free to rotate and can taken suction from the sea.

- The sprinkler system “open-close valve” is free to move

These tests are then required to be done by the maker during the annual thorough inspection of the lifeboat.

Lifeboat sprinkler system lines do not like the seawater to be retained in it for long time as the salt can block the nozzles. For this reason we must flush the sprinkler system with fresh water each time we test it with sea water.

Lifeboat Launching Appliances

Lifeboat needs some means to lower it. We should be able to lower Lifeboats without depending upon the ship’s power supply. That makes the gravity type lifeboat davits a first choice for the shipyards and ship owners.

In this type of launching appliances, we just need to release the brake to lower the lifeboat.

SOLAS require that we test these launching appliance periodically. After all our friend’s friend is our friend too. Isn’t it ?

Let us see how regulations require us to take care of the launching appliances

a) Annual thorough inspection of lifting appliances

Ref: SOLAS III/20.11.1.2 and MSC.1/Circ.1206/Rev.1/Appendix of Annex 1, para. 2.8 and 2.9 as applicable

SOLAS require the Maker to carry out annual thorough inspection of the lifeboat launching appliances.

The launching appliance have different components and MSC circular provides complete guidance on element to check on these components. Let us see what elements are inspected during annual thorough inspection

i) Lifeboat Davit

Every year, lifeboat davit is checked for any

- corrosion, misalignments, deformations and excessive free play

- lubrication of wires, sheaves and moving parts

- functioning of limit switches

- Any stored power systems or hydraulic system

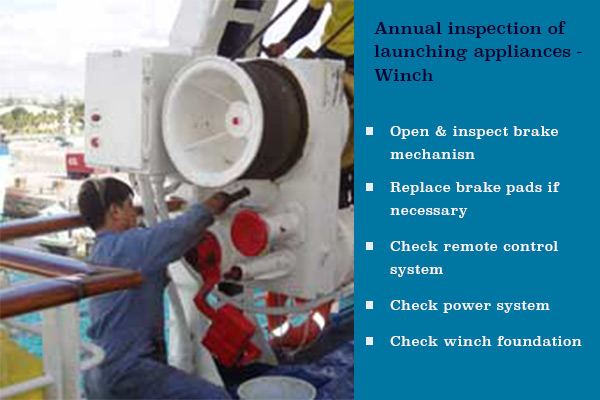

ii) Davit Winch

The main element of a davit winch is the braking system. If the brakes are not in good condition, lifeboat operations are liable to cause accidents.

There are two brakes in the gravity type lifeboats. One that holds the vessel (static brake) and second that controls the lowering speed (centrifugal brake).

During annual inspection by the maker, the brakes are opened up and condition of brake pads is checked. The brake pads are replaced if required.

Other than brake pads, the inspection of davit winch includes

- checking the condition of remote lowering system. Remote lowering of the lifeboat is done by a small wire that leads to inside the lifeboat. Pulling this wire lifts the brake handle remotely which lowers the boat. Sometimes you will also find remote lowering system on lifeboat deck from where the lowerer can visually see the lifeboat overside.

- Checking the power supply system for hoisting the lifeboat

- Checking the visual condition of winch foundation to ensure that it can take the load of the boat.

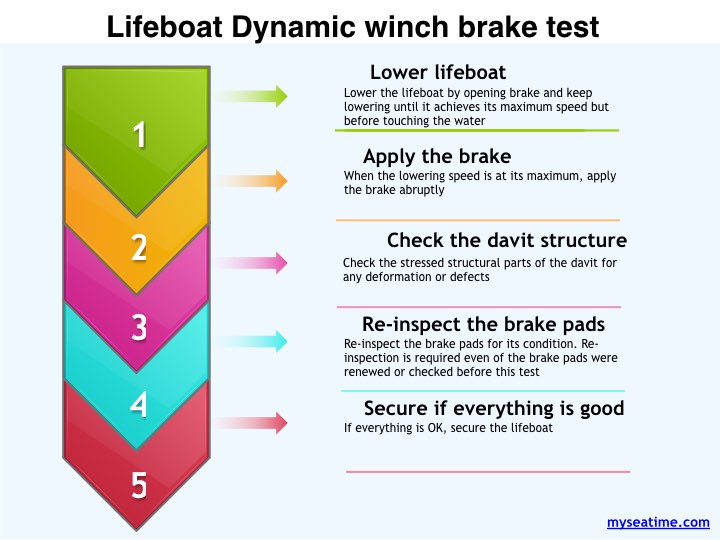

b) Dynamic winch brake test

Winch brake is an important part of the launching system which if fails can result in disastrous situations. So it is not just enough to inspect the which brake and replace the brake pads.

SOLAS require the maker to perform dynamic winch brake test. In the dynamic brake the boat is lowered by opening the brake. When it achieves the maximum lowering speed, the brake is applied abruptly. The brake pad and davit foundation is then inspected.

i) Annual winch dynamic brake test

Ref: SOLAS III/20.11.1.3 and MSC.1/Circ.1206/Rev.1/Appendix of Annex 1, para. 3.1 and 3.3 as applicable

Every year the dynamic load test is done with weight of the boat and its equipments.

ii) 5 Yearly winch dynamic brake test

Ref: SOLAS III/20.11.1.3 and MSC.1/Circ.1206/Rev.1/Appendix of Annex 1, para. 3.2 and 3.3 as applicable

Every 5 years the dynamic brake test is done with the weight of the lifeboat and its equipment alongwith the weight of the number of persons that lifeboat is designated for.

For the calculation, the weight of a person is taken as 75 Kgs. But for the following vessels the weight of the person is taken as 82.5 Kgs

- Cargo vessels with keel laid on or after 01st July 2010 or where lifeboat is installed after this date.

- For all other vessels with keel laid on or after 01st January 2012 or where lifeboat is installed after this date.

Conclusion

Shipping has become safer nowadays but even the unsinkable ship had to use the lifeboats on its maiden voyage. And when they required it, either the lifeboat was not ready or the people handling it.

The design and other requirements about lifeboats have changed drastically since then. All it requires now is for us to make sure that we follow the routine set out in SOLAS, company manual, MSC circulars and any other regulations.

Share this:

About Capt Rajeev Jassal

Capt. Rajeev Jassal has sailed for over 24 years mainly on crude oil, product and chemical tankers. He holds MBA in shipping & Logistics degree from London. He has done extensive research on quantitatively measuring Safety culture onboard and safety climate ashore which he believes is the most important element for safer shipping.

Search Blog

33 Comments

sir can u tell, technical difference between rescue boat and lifeboat (if using lifeboat as rescue boat) except the hoisting requirement.

Except hoisting speed requirements (including requirement to have emergency source of power for winch), the rescue boat need to have recovery strope for quick recovery of the rescue lifeboat.

What are the monthly checks for fire extinguishers

That is a broad question Vijeesh..I will try to cover that in future..If you have any specific question about that, you can always ask that in our SEAQA section..

VERY USEFUL INFORMATION SIR THANK U

Thanks Munnangi...

Thanks a lot sir! Very interesting and useful article. I opened even something new for myself. It would be great if you'll make a separate topics, for example "navigation", "safety", etc. Or use hashtags for more easy searching.

Great Idea.. Thanks. Will think in that line and implement soon.

What is the maintenance routine for the GRP hull of the rescue boat? And what part of SOLAS covers this? Thankyou1

Can send full ffa notes sir....

Good day sir, Very useful blog about LB maintenance sir. Like to get ur attention in 5 yearly dynamic winch brake test,in which u missed 1.1 times of weight of LB ,its complement and equipment to be used for testing. Kindly note it sir. Thank u.

hello sir, could u tell me what certificates are checked by surveyor for lifeboat and rescueboat when they onboard>?

please enlighten me about where is harbour pin and how it looks?and procedure for lowering lifeboat

Thanks a lot sir..

very good information sir, thanks alot.. Here, i have a question sir, could you tell me please sir, is there a limit switch for freefall lifeboat? Normally, where is it (position?) Thank you...

List of Life boat certificates

I want to buy 1 lifeboat How much INR price.

Excellwnt blog content as always. One question though, when you say "moving out the lifeboat" what part of the davit should we move? For how much? Thanks and mire power!

Is there any drain plug in Free fall type lifeboat?

Very useful information sir regards and thanks

Very useful info. Sir kindly clarify that the lifeboat wires are to be renewed every 5 yrs . End to end change doesnt exist anymore

We have to change the wire falls completely and not end to end

Thank you for this wonderful blog sir. I just want to ask regarding free fall lifeboat if you tested the sprinkler and flush it with fresh watet but not that much strong pressure. Is there any effect on starting the engine? Of the lifeboat? Hope to hear more from you sir

perseverance can conquer any one **.

perseverance can conquer any one **.

Someone please tell me the circular ref where it mention that; 1. Cargo vessels with keel laid on or after 01st July 2010 or where lifeboat is installed after this date. 2. For all other vessels with keel laid on or after 01st January 2012 or where lifeboat is installed after this date.

Nice blog sir

Thanks for this post…As one of the most trusted Hydro testing services in UAE , we ensure your piping and systems are up to the task. Our Eiwaa is best Pressure Testing companies in UAE and also Pipe Freezing Services .Pipe freezing is a method of liquid nitrogen applied in the outer surface of pipes to lower the temperature of pipes .When the temperature of pipes lower than the pipe fluid below its freezing point, create a freeze plug capable to withholding pressure up to 4000psi.Pipeline freezing is used for valve/pump replacement, pressure testing and HVAC System maintenance etc. Hydro Testing Services Water bag rental in Saudi Water Bag Rental UAE

Sir , been reading your articles since long... Jst have a question how and what is the requirement of lifeboat 5 yearly test how are they carried ou!

Good explanation...can I know the length and thickness of the release cable for totally enclosed lifeboat port and starboard...thanks for answering all questions..bravo

Kindly confirm Dynamic Test is stated as operational test however can anyone explain about static test as this uses 1.5 times ships total weight of craft capacity and instrument done every 5 years

Leave Comment

More things to do on myseatime

MySeaTime Blogs

Learn the difficult concepts of sailing described in a easy and story-telling way. These detailed and well researched articles provides value reading for all ranks.

Seafarers Question Answers

Ask or answer a question on this forum. Knowledge dies if it remains in our head. Share your knowledge by writing answers to the question

MySeaTime Podcast

This podcast on the maritime matters will provide value to the listeners. Short, crisp and full of value. Stay tuned for this section.

Exceelent piece of information .A must read for seafarers.

Thank you brother...